Isesengura Ryimashini ya CNC Ikibazo cya Batiri ya Aluminium

Ibisobanuro birambuye

Icyifuzo cy'abakiriya

1. Kora igice nkuko biri muri dosiye ya 3D kandi ugenzure neza muri 0.05M.

2. Ubugenzuzi bwa CMM bivuga kwihanganira gushushanya 2D.

3. Menya neza ko inteko ari Ok.

Isesengura ryacu

Nyuma yo kwakira ibishushanyo byabakiriya nibisabwa, injeniyeri zacu zumwuga zifite isesengura ryuzuye kandi ryemeza ko dushobora kubyara iki gice kandi tukagenzura ibipimo byose muburyo bwo kwihanganira.Kugirango tumenye neza ko inteko ari nziza, twasabye umukiriya gutanga igishushanyo cyInteko kugirango turebe ko nta nkomyi n’ibindi bice.

Tangira gukora

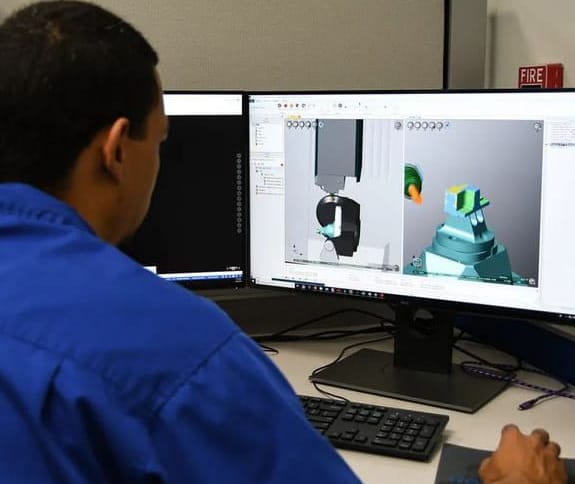

1. Porogaramu

Porogaramu yacu ya CNC iri gukora mugushiraho inzira zakazi za mashini.

2. Gutunganya CNC

Igicuruzwa kirimo gutunganywa kuri gahunda kandi neza nkuko inzira za gahunda twashyizeho.

3. Amaboko meza

Ubuso busanzwe bwibicuruzwa nyuma ya CNC birakaze kandi hamwe na burrs hamwe nicyuma, Umukozi wacu ubu arimo gukoresha sandpaper kugirango asibe kandi asukure hejuru kugirango agire igice cyoroshye nta mpande zityaye.Igice kizashyirwa kumusenyi kuva mukigero kugeza kumusenyi mwiza (400-1500) urwego rusya kugeza hejuru.

4.CMM (guhuza imashini ipima) Kugenzura

QC yacu irimo guhindura imashini ya CMM kugirango igenzurwe neza kubijyanye nukuri, aho ihagaze neza, geometrike nukuri neza.

5.Kwohereza

QC yacu imaze gutanga urumuri rwicyatsi kubicuruzwa, tuzabohereza hanze hamwe nibikoresho bikomeye byo kurinda ibicuruzwa.Kugirango ibicuruzwa byose bizatangwa muburyo bwiza.